COURSE AIMS

To provide thorough practical and theory plant training in operating a Skid Steer Loader,to enable the candidate to competently and safely carry out the role and pass the Theory and Practical Tests.

COURSE CONTENT

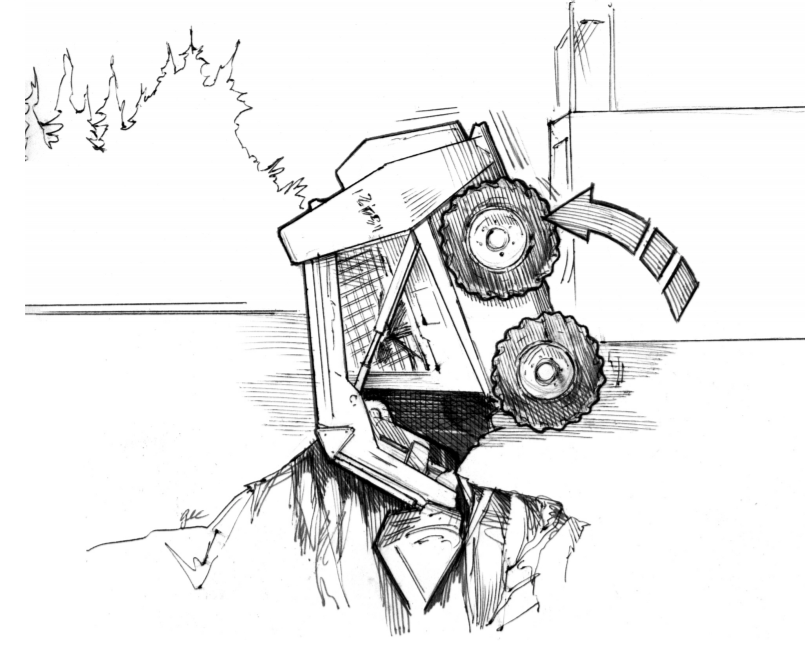

- Name and explain the purpose of principle components, the basic construction, controls and terminology

- Conform with manufacturers requirements as per the operator’s handbook, other types of information source and relevant regulations and legislation

- Undertake all pre-use checks

- Configure and set for site and highway travel

- Travel over rough, undulating ground, substantial inclines and level surfaces; laden and unladen

- Manoeuvre plant in confined spaces

- Configure and set for extraction and loading duties

- Explain actions required for hazards, underground and overhead services

- Extract differing types of materials from stockpiles and other sources

- Form stockpiles of segregated materials and construct (temporary) ramps

- Sort and place materials into transporting vehicles and hoppers

- Spread and level ground and materials

- Carry out shut down and securing procedures

- Explain the loading and unloading procedures for machine transporting

Skid-steer loaders present a number of risks to workers. The most types of injuries caused by skid-steer loaders are rollovers on soft or steep ground and crush injuries when safety features have been bypassed or removed, and during maintenance.

Workers can be:

- Pinned between the bucket and frame of the machine or between the lift arms and frame.

- Struck and crushed by the bucket, bucket arms, or material falling from the bucket.

- Injured in rollovers and runovers.

Below we will explain three incidents by steer skid loader and some or information on the safe operation of skid-steer loaders.

In recent years there have been several fatal accidents involving skid steer loaders. Operators have been crushed when they exited skid steer loaders with the lift arms raised or when they operated controls from outside the cab. They have also been run over after leaving the controls with the engine running.