Slinger / Signaller Training

The Ribble Valley Slinger / Signaller course content is very comprehensive and so cardholders are able to use their skills when performing Slinger / Signaller duties with any type of lifting equipment, not just lorry loaders. The Slinger / Signaller course consists of 15 modules (The course duration is one day for experienced candidates and up to two days for novice candidates. A maximum of four candidates can attend a course. Both courses culminate in a written and practical examination.

The assessment process is set by Ribble Valley and administered by the Instructor. It consists of two theoretical assessments and one practical. The theoretical assessments consist of a set of multiple choice and ‘open’ questions. The practical assessment is designed to identify whether the candidate has the appropriate practical skills to perform their duties as a Slinger / Signaller safely and efficiently.

Upon successful completion of the course every candidate will receive a certificate, and will be registered on the Ribble Valley database. The certificate are valid for three years, after which time refresher training and assessments will need to be undertaken. Candidates also receive the Ribble Valley Slinger / Signaller manual, which is used as a reference guide throughout their career.

The strength of Ribble Valley training comes from the technical and training knowledge on its Training Standards Committee. The Committee is made up of training and technical professionals from all the major loader crane manufacturers and importers within the UK. In addition, the Health and Safety Executive is represented. The Committee develops, consults upon and maintains all the training standards set by Ribble Valley

Course Objectives Slinger Signaller – Subject to what your employees’ duties cover, not all the objectives will be covered.

- Define Slinger Signaller roles & responsibilities.

- Explore and analyse all relevant legislation and regulations.

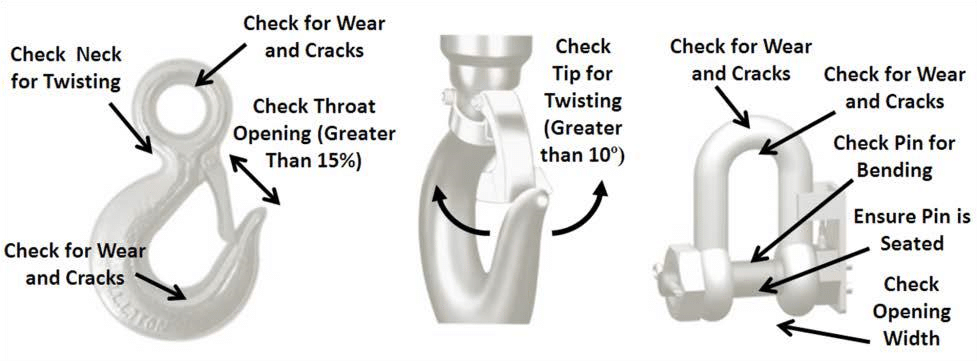

- Carry out pre-use inspection checks, identify communication method and lifting accessory prior to lifting.

- Maintain safe working situations.

- Conform with manufacturer’s requirements as per technical data.

- Explain procedures for placing non-serviceable items out-of-service.

- Establish the weight and dimensions of loads, identify centres of gravity and ensure load balance, security and integrity.

- Communicate the weight and dimensions of loads to the crane operator, direct and guide the movement of loads to different types of locations (accurate placement)

- Employ clear and unambiguous signals to direct the actions of a crane moving loads.

- Secure various types of loads to a lifting hook using the relevant lifting accessories.

- Carry out-of-service and securing procedures.

- Check equipment for function and serviceability including slings.

- Lift 3 different loads from ground level to various specifications including, 180° and 360° slews.

- Land the loads at various points with various radius.

- Secure all loads and ensure they are made safe following each activity.

- End test – theory.

• End test – practical (external area practical test slinging/signalling for the movement of loads)