G4- TELESCOPIC-CONTAINER-HANDLERS

Thanks for taking the time to view our web site. We only offer training to companies. We don’t offer any training to the public

We will send our friendly qualified instructor to your site to train you and your staff.

On site block training e.g. 6 certification-refresher- training and test over 1 day.

We will not be beaten on the quality of our training and the block booking cost.

We are the home of the Guaranteed Pass.

For full details please contact Steve 07711 306605. / Adam 07543 129437

We only offer training to companies. We don’t offer any training to the public

Novice Forklift Operators Course

This course is suitable for operators with limited or no previous experience.

Course content includes: knowledge of the safe loading of equipment and its manoeuvring limitations. Extensive practical training with instructor assessment, ensuring operators are fully aware of Health & Safety legislation. Successful completion of the course is subject to verbal and practical tests.

The law states courses for a novice operators would typically last 1-3 days.

Experienced Forklift Operators Course

This course is for the forklift operator who has around 12 months operating experience but lacks any kind of formal training or licenses. Successful completion of the course is subject to a theory and practical test.

Please call to discuss individual requirements.

All forklift training courses are carried out on your site:

We will require:

- A Suitable area/room for the Theory Session

- A Suitable Area for Practical Sessions

- An Appropriate Machine

- Suitable Load for Practical Training

Refresher Forklift Operators Course

The purpose of a Refresher course is to correct any bad habits and check that Health & Safety legislation is being adhered to (including keeping equipment in good order).

Successful completion of the course is subject to a theory and practical test.

Conversion forklift course

Conversion Training for those operators who already hold a certificate on one type of forklift truck, but would like to gain a certificate for an additional type of forklift. Successful completion of the course is subject to a theory and practical test.

All forklift training carried out to ITSSAR approved International standards, as recommended by H.S.E. ACOP Approved code of Practice. (L117).

What is Container Handling?

While it is obvious by the name, some of you might not be familiar with container handling. If you have ever been to a port, then you must have seen tall stacks of hundreds and thousands of shipping containers. As these containers need to be moved around for shipping via ships, you need to have proper container handling.

Thus, container handling simply means to safely and properly manage and move shipping containers around a port. Generally, this is done using equipment like forklifts container handlers, cranes, and more, as you will learn later on in this comprehensive guide to container handlers.

Container Handling Techniques

Before going further with the comprehensive guide to container handlers, it is important to understand the general overall procedure used for handling containers. Even though different ports may use slightly different techniques, here are some of the most common container handling techniques:

- Securing Cargo: Since a container can have a lot of items inside, all of them need to be secured so that they don’t move around during shipping and get damaged. This is done using wooden crates, packaging materials, metal beams, and more. Similarly, the containers themselves are also lashed and shipped securely.

- Optimal Container Size: Depending on the items that you are shipping, choosing the right-sized shipping container is highly important due to logistics costs. While some items can be shipped in a smaller 20 feet container, others might need a 40 feet one.

- Shipping and Handling: Once everything is secured, the containers can be shipped around the globe. And for both sending andreceiving containers, you will also need to perform container handling using forklifts, container handlers, cranes, and more.

Types of Container Handling

Coming back to the comprehensive guide to container handlers, it is highly important to ensure that you are choosing the right type of container handlers as well. Hence, here are the three main types of container handlers available out there:

Industrial Container Handlers

Industrial containers or reach stackers are the most common types of container handlers available out there. These are highly versatile since they can easily handle tall stacks of containers without breaking a sweat. More importantly, these are powerful enough to handle both loaded and empty containers alike.

Empty Container Handlers

Speaking of empty containers, since a port will also have a lot of empty containers lying around, you will also need to move them. Thankfully, because empty containers are much lighter, you can get away with empty container handlers Such container handlers are much cheaper, which makes them perfect for use exclusively for empty containers.

Loaded Container Handlers

Similarly, if you are moving heavy loaded containers around the port, then you should be using a loaded container handler. These are essentially forklifts with a top pick-grabbing mechanism. Because of this design, you can even make tall stalks while working with loaded containers without any issues.

Safety Considerations for Container Handling

Even if you have the right type of container handler, it is still highly important to use it correctly and safely. Thus, we have also mentioned the following safety considerations in this comprehensive guide to container handlers:

• Proper Training: Before anyone starts using heavy-duty container handlers on your port, they should first go through proper training. This ensures that they won’t make any mistakes that can

potentially lead to major accidents.

• Equipment Maintenance: Even if all your operators are well trained, they are still at risk if your equipment is not maintained. Hence, it is highly important to keep your container handlers serviced regularly.

• Hazard Identification: Whether it’s a visitor at your port or a new crane worker, it is highly important to let everyone know of possible hazards. Thus, all-hazard points should be clearly marked for accident prevention.

What Equipment is Used for Handling Containers?

Apart from container handlers themselves, there are still many other equipment and gear that you will find at a port. So, to make this comprehensive guide to container handlers even more helpful, here are some of the common equipment used for handling containers:

- Forklifts: A forklift is only useful for basic tasks and lightweight work. Because these can only lift one container at a time, they are not ideal for large-scale applications.

- Reach Stackers: These are perfect for picking multiple rows of containers at once, making them highly versatile.

- Container Handlers: With these, you get the best performance for heavy-duty usage on a port for moving around containers.

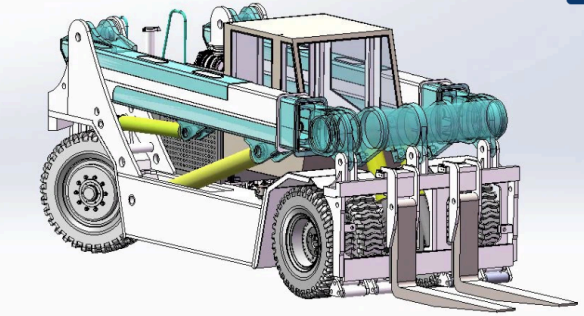

Key Components of Container Handlers

Similar to any other vehicle or industrial equipment, it is highly important to know all of the key components of your container handler. And while these components vary from model to model, almost all container handlers out there will have these key components:

- Chassis: This is the frame of your container handler, which gives it rigidity and structure for heavy-duty tasks.

- Mast: The mast is responsible for guiding the fork of your container handler while lifting containers.

- Forks: Without a proper fork, you won’t be able to lift heavy containers.

- Hydraulics: These are responsible for moving all the various parts of your container handler up and down.

Best Practices for Operating Container Handlers

Last but not least, any comprehensive guide to container handlers will not be complete without some real-world practices that you should follow. If you want to get the most out of your container handler, it is highly important to follow practices like:

- Automation: All tasks should be automated wherever possible for maximum safety.

- Load Stability: Whenever you’re stacking containers, the load should be balanced to avoid damage.

- Safety Gear and Clothing: Everyone should have equipment like helmets, gloves, visors, high visibility vests, etc.

- Equipment Capacity: All equipment should be used under the given capacity to avoid any accidents.