The warehouse and its surrounding area is one of the most dangerous working environments and protecting your employees, as well as visiting operatives, should be your number one priority.

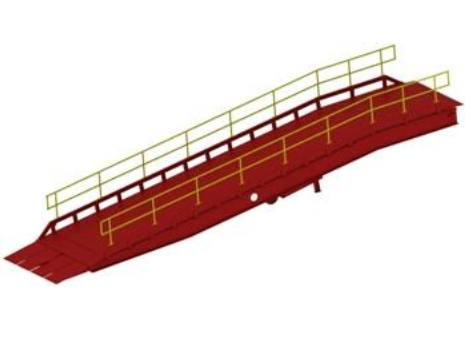

Choosing the correct loading solution for your specific needs, be that a modular dock, a mobile loading ramp, or a complete loading dock, is important in creating a safe working environment and instilling confidence in your staff. However, it is only the first step.

Loading dock accessories, from lights and wheel chocks, to guidance signs and safety mirrors, add that extra level of safety making the loading environment even more secure.

DOCK LIGHTS

Dock lights are an essential addition to any loading dock. They help to illuminate dark corners within the vehicle where natural light does not reach. Overall, dock lights provide staff with a clearer view of their working environment and can help to prevent potential accidents.

SAFETY BARRIER SYSTEMS

Providing your staff with safe areas to work via Safety Barrier Systems which separate your employees from the movement of mechanical handling equipment, is becoming more and more important as facilities become busier and time pressures increase.

TRAILER SAFETY SUPPORTS

Trailer Safety supports are designed to provide additional support under the fifth wheel of a parked container when the cab has been removed and the loading and unloading process is taking place.

LOADING DOCK SAFETY INTERLOCKS

While every effort can be made to control driver actions the introduction of Safety Interlocks to the loading dock and yard ramps provides another layer of protection by locking onto the red emergency ‘suzie’ air hose connector on your trailer.

WHEEL CHOCKS

Wheel chocks are an affordable, yet reliable and effective way of minimising the movement of a vehicle whilst it is parked or as its being loaded and unloaded. Although we know every measure is taken to ensure a vehicle is parked safely, accidents can occur. But these small additions to your loading dock can minimise these incidents.

TRAFFIC CONTROL

One of the most potentially dangerous features of a warehouse is the constant stream of – often large – delivery vehicles. Controlling where these vehicles go and ensuring it is clear when they are stationary or on the move is an effective way of keeping staff safe.

Clearly marked signs directing traffic around a site will help delivery drivers know exactly where they need to go. Traffic light systems, both around the site and on the loading dock itself, will help to control the flow of traffic, as well as inform staff working around the vehicle when that vehicle is stationary and when it is about to move.

Strategically placed mirrors will also provide drivers and staff alike with a clearer view of their working environment.

Ribble Valley Training Centre has years of experience in advising customers on the best way to manage their traffic flow effectively, how to keep their operatives safe, and how to ensure they provide the safest working environment possible – and we can help you too